Theodora (K&ESR No. 51)

“Theodora was built in 1926 by the Metropolitan Carriage and Wagon Company, Birmingham. One of just six specially built for the London Charing Cross to Hastings line, she provided a majestic, well-loved means of transport around southern England for almost forty years.

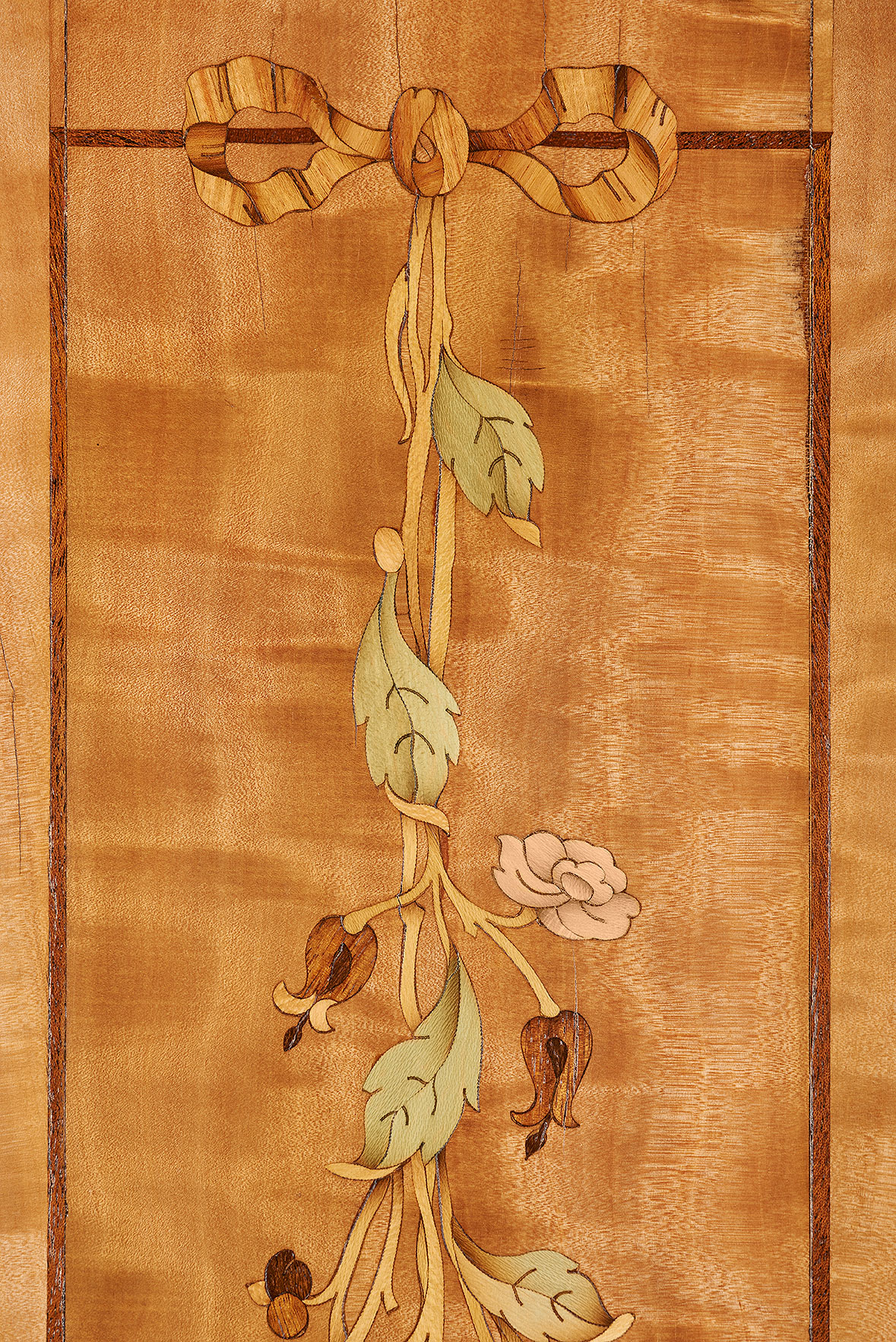

The Kent & East Sussex Railway were able to save two of these ornate Pullman carriages from the scrap heap in 1963. Sadly the ornate marquetry had been damaged by years of water ingress, but with the help of Wheathills, Theodora can now be sympathetically restored to her former beauty.

Funds are being raised from well-wishers, past passengers, enthusiasts and local families; a whole community of people are getting involved in this worthy project. These funds are carefully assigned to each aspect of the restoration, and Wheathills part in this endeavour has now begun.”

Sample marquetry has been created...

A frieze has been restored...

The first panel has been dismantled

The veneers and marquetry have been repaired and a new special half hour fireproof finish has been applied. This has been designed to simulate traditional hand French polishing.

Restoration of Panel "Number 3"

October 2019: The restoration work on the Theodora panels continues. This panel labelled 'number three' requires a great deal of thought to successfully blend conservation and restoration together. Not only are there sections of the veneer missing, the bottom of the panel is broken and the sub-structure of the panel has totally de-laminated. This requires reconstructing before any other work can commence.

After cleaning off all the dirt and grime the craftsman can evaluate what timbers are required to restore this beautiful panel back to a more acceptable condition.

All loose pieces of veneer are carefully re-glued back into position using animal glue which was used when the panel was originally created

Once this work has been completed its then time to select suitable pieces of veneer from Wheathills vast stocks. These are then cut into shape before being glued into position.

Whole sections of this panel were created as the original was so badly water damaged with black tannic acid reaction that these areas were taken out and replaced with new. The new sections were colour blended to the surrounding shades.

Once all the work was completed, pigments and polishes were mixed to create a finish to complement the aging process. Once the colour matching was complete a French polish based fire retardant was applied by hand over many hours to achieve a traditional French polish appearance.